Implanting innovation

Leverage the latest innovations to reduce costs, advance quality and extend your production capacity.

Orthopedic Implant Manufacturing

Leverage our agility, ingenuity, automation and low-cost base to drive down your cost of manufacture.

Additive Manufacturing

The expertise, technologies, and scale to deliver end-to-end, world-class, additive manufacturing solutions.

Medical Component Manufacturing

Leverage precise, state-of-the-art Swiss turning technologies to manufacture high quality, complex components.

Capabilities

Joint Partnership

We help drive progress for our medical device customers by enhancing both their production capacity and their product and process innovation.

Manufacturing Capabilities

The facilities, technologies and processes to deliver end-to-end manufacturing.

Value-Add Capabilities

The team, expertise, and ingenuity to drive tangible added-value for our customers.

Devices

Extend capacity & reduce costs

Tap into our passion for innovation and we’ll help advance quality, extend your capacity and cut production costs.

Knee Implants

Femoral implants, patella and tibia implants, and limb salvage.

Hip Implants

Hip stems, acetabular cups, femoral heads and femoral liners.

Spine Implants

Interbody cages, pedicle screws and rods, and SI fixation screws.

Trauma & Extremities

Shoulder & elbow, foot & ankle, tibia & femur, hand & wrist, cranial & maxofacial.

Additive Manufacturing: Understanding Process Validation Requirements for AM Orthopedic Products

Croom Medical has been a pioneer in the development of metallic additive manufacturing within the SME orthopedic sector since 2010. With Additive Manufacturing (AM) and ...

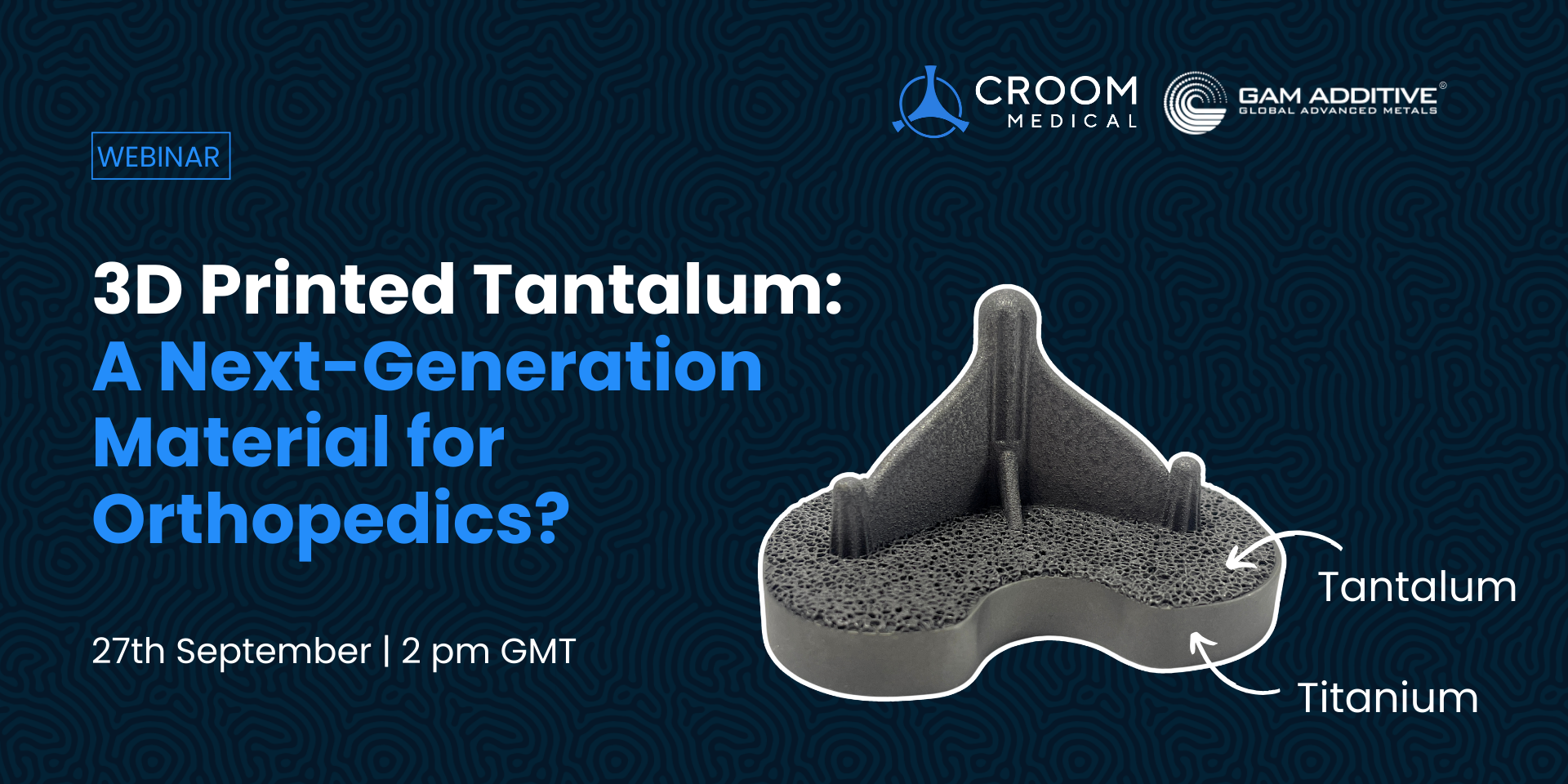

Croom Medical Partners with Global Advanced Metals to Present Breakthrough Tantalum Additive Manufacturing at OMTEC 2023

Limerick, Ireland – June 8, 2023 Croom Medical, a trusted leader in orthopaedic contract manufacturing, is pleased to collaborate with Global Advanced Metals (GAM) for ...